On-site nitrogen, affordable and sustainable productivity

The air we breathe is composed of 78% nitrogen, 20.9% oxygen, 0.96% argon and 0.04 carbon dioxide and other rare gases. Nitrogen is an inert gas that lends itself to a variety of uses. We at Isolcell were among the first to develop different applications and to make it easily available to businesses. Traditional methods of supply such as with high pressure cylinders, liquid nitrogen tanks and storage tanks create various difficulties for companies: costs of transportation, risk of supply delays, need to have a dedicated space and confined space, periodic checks on safety and maintenance, etc. These problems result in often unpredictable and significant costs. Awareness of these issues led us, some time ago, to study an alternative, more affordable, functional and ecological system: on-site production of nitrogen via autonomous generators. On-site production brings clear benefits to companies. First, they can count on a steady and punctual supply that does not depend on external supply. They can realize significant savings by cutting procurement cost and can count on leaner and more rational operability. Local production of the amount of nitrogen needed at the desired purity can be started and stopped out with immediacy and without waste. Our nitrogen generators have been optimized for different applications and are adaptable to different needs. Our business philosophy is based on continuous improvement and we are proud to offer only the best state of the art solutions and technologies. Our strength lies in our meticulous and highly skilled staff able to advise and support customers with each particular request or customization in order to guarantee the achievement of requested objectives.

How does a PSA generator work?

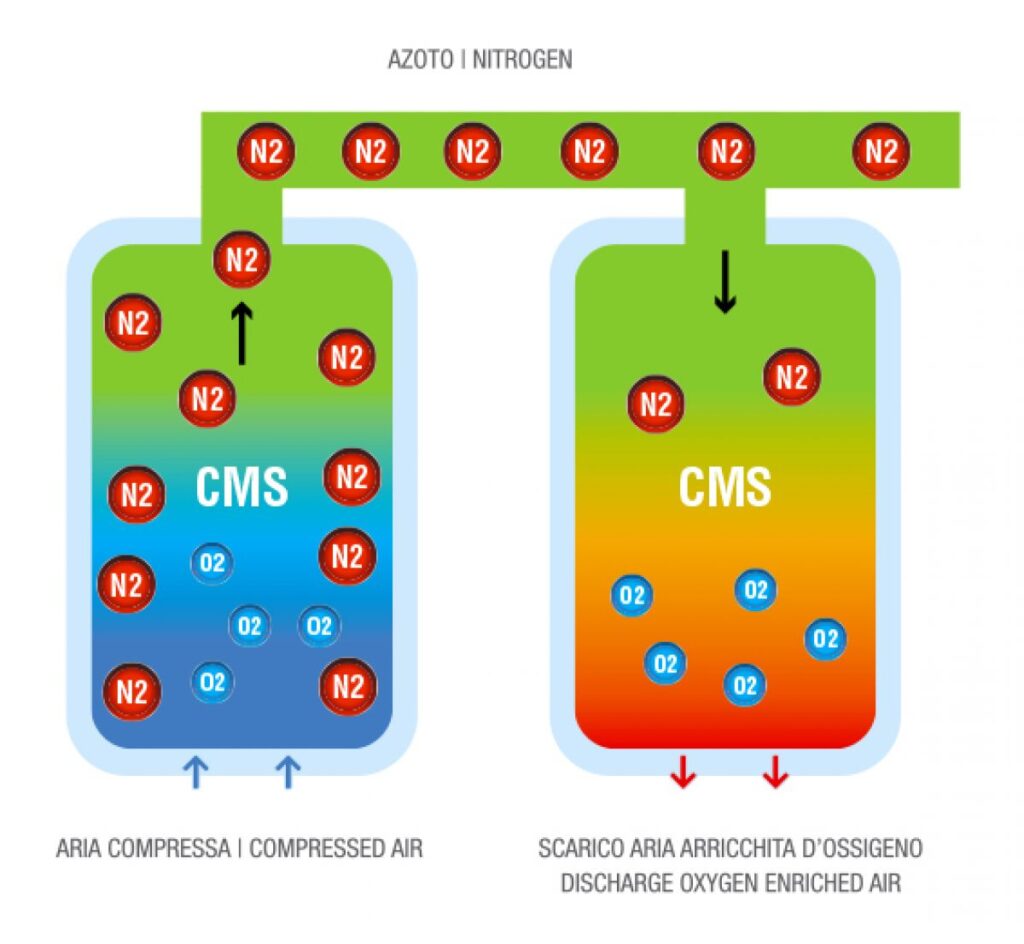

Page 12 The new M-S-D Series Nitrogen Generators are the latest evolution from traditional PSA (pressure swing adsorption) systems and allow you to produce nitrogen continuously from compressed air. The M-S-D Series Nitrogen Generators consist of one or more modules of two columns filled with the highest quality molecular sieves of extremely fine porosity offering high performance and selectivity. The compressed, dried and filtered air passes through one of the two filtering columns, which retains oxygen, residual water vapour, and other rare gases. When the filtering column is saturated with oxygen, it is depressurized by discharging the oxygen into the air. At the same time the compressed air is diverted to the other column, where the oxygen is surrended until the next change. This cycle will continue uninterruptedly in order to fill a storage tank, which acts as a buffer to absorb any peak of demand and to ensure the continuous supply of nitrogen to the process. When the tank reaches the maximum fill pressure, the generator is automatically put into stand-by mode, in anticipation of a new demand for gas.

Control system

All PSA NL M, S and D generators are equipped with a residual oxygen analysis system that monitors the generator’s operating parameters.

Control System

Homogeneous filling

Over the years, Isolcell has perfected in its generators the delicate filling process with column filtering CMS sieves. Our system, based on three distinct operations and subsequent checks, allows optimal and consistent filling of each individual column while simultaneously solving the problem of mechanical wear over time, dust formation and the need to top up filters typical of PSA technology.